Foam Flooding System

A foam flooding system is a type of fire suppression system that uses foam to extinguish fires. It is typically used in industrial facilities, such as oil refineries, chemical plants, and power plants, where flammable liquids and gases are present.

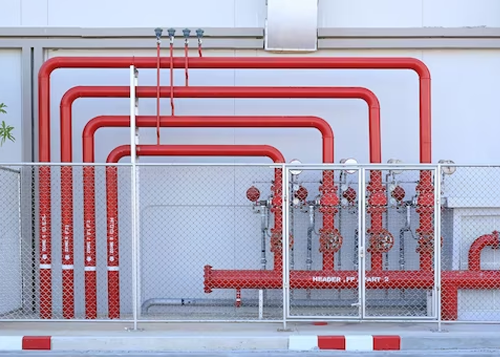

The foam flooding system consists of a foam storage tank, a foam concentrate pump, and a network of pipes and nozzles. When activated, the foam concentrate is mixed with water and distributed through the nozzles, creating a layer of foam that covers the fuel surface and separates it from the oxygen in the air, suppressing the fire.

The foam flooding system can be activated manually or automatically, depending on the system's design and the facility's requirements. Automatic activation may be triggered by fire detection sensors or heat sensors, which detect the presence of a fire and activate the system.

Foam flooding systems can be designed to deliver different types of foam, depending on the specific fire risk and the facility's requirements. High-expansion foam, for example, is used to suppress fires in large open spaces, while low-expansion foam is used for smaller, confined spaces.

Proper installation, testing, and maintenance of foam flooding systems are critical to ensure their reliability and effectiveness. Regular inspections, testing, and repairs can help identify and address any issues that may impact the system's performance in the event of a fire.